12 VOLT BATTERY ADDITION, BUYING BATTERIES AGAIN/ Add on accessories pt 2

12 volt battery capabilities are always a concern on any power boat no matter what the size. I have broken the requirements and battery set up into five different groupings. Each one of these battery set ups and tips will describe different types of power boats and there battery set ups.

1- The first battery set up is a

small power boat which is designed and sold to be a trailer boat. This boat will be living its life when not out on the water on a trailer. This type of boat will come rigged with a single start battery system, no charger (the simplest set up). This battery set up works fine, provided the boat comes out of the water at the end of each time you use the boat. A boat that does not have to live in the water all the time escapes several issues that effect battery life. When the boat spends its stored life on the trailer the drain plug is out and the boat drains free of any rain water or boat wash water. The boat does not rely on the battery to power the bilge pump to get rid of excess water when you are not around. As long as the battery in this set up is keep charged it will likely out last a battery in a cruiser as it is not being constantly charged up.

If you put this same boat in the water full time at the dock, the boat now can become filled with rain and any water that finds its way to the bilge area is pumped out by the bilge pump. The water will get in even with the canvas on. The reason for this is the requirements to seal all the hardware on a smaller boat are different than a larger boat (a bow rider for example requires no sealant on deck hardware). If it were to rain all week for example the bilge pump would have to come on several times to keep the boat from filling up.

Trailer note (if you leave the drain plug in the boat while you store it on the trailer you can run into the same issue). After a week of rain you show up to go boating and the battery is low on charge. So after a month at the dock the battery will probably be dead. Out comes the jump box to start the boat, you do this several times and you have done damage to the battery, and you find you are buying batteries every year.

The immediate fix to this is install a second battery.

Does this fix the problem? No its does not by installing a second battery all you are doing is extending the battery life which means that the bilge pump will run longer and your boat will start more often. If you install a new battery with an old damaged battery the new one will continually drain to the old battery. You must remember that newer motors require a full battery charge to start, if you are starting your motor on low voltage you are harming the starter, electric fuel pumps and or any other systems on the motor that require 12 volts and full battery amperage to start. If you continue this low voltage starting you will be doing long term damage shortening the life of the equipment on the engine. To prevent this from happening install a battery switch with your two batteries at the very least, this will allow you to isolate a start battery. If you tie two batteries together with out a switch you are going to wear down the batteries equally . You will have to be sure that when you install the battery switch that it is the correct one a two position battery switch 1/2/ALL/OFF, and you must also make sure that the battery you isolate is the start battery be sure that it does not have any other boat system wiring attached to it

. This is a is engine start only battery ( the only other wires attached here are for the trim pump). Keep in mind that the only system on the boat that must be hooked directly to the house battery (this is the accessory battery) is the bilge pump(s). Be sure that every circuit that leaves the battery is fuse or breaker protected, if you have any wires hooked to the battery that do not have circuit protection remove them , pick up and install a circuit protection devise protection device.

SINGLE MOTOR ONE BATTERY

SINGLE MOTOR WITH TWO BATTERIES

2- The next battery set up is the one you will find in the small cruiser classes of boats. These are boats which are designed and sold to be kept in the water all season. Some of these boats are considered over night types, these do not have a 120 volt shore power system installed from the factory, but are wired for dual batteries complete with a battery switch. This design will have a location for a start battery and a deep cycle house battery. It is important that the correct batteries are in the correct location. You can start a boat with a deep cycle battery, however the cranking amps needed at start are not instantly there for the motor. a start battery does not have the recovery of a deep cycle (deep cycle batteries take longer to completely charge and if they are low you can quite often turn everything off and the battery will have a natural recovery of some power this is why they are accessory battery). Be sure you match the start battery with your engine(s) needs not enough cranking amps will harm the motor. Your battery switch allows you to keep the start battery isolated from the systems such as radios, accessory plugs lights etc. This will give you the peace of mind knowing that even if the house battery goes down from using the systems for extended times your boat will start and with the reselection of the battery switch after start up the alternator will charge the low house battery.

How do you use the battery switch as a tool to keep the start battery fresh and ready to go?

The first thing you must do is have a clear understanding of which one of the batteries is the start battery and which one is the house or accessory battery. Once you determine the start battery mark the switch with an S beside the number that it corresponds to (the battery switch is marked 1 2 ALL and OFF)

If your start battery is attached to the number 1 terminal than number 1 is the start battery and number 2 is the house battery.

So here is how we use the switch: When you get to the boat and you are prepared to start the motor select number 1 or the start battery once the motor is running switch the switch to all. This allows the alternator to distribute the charge it is producing to both the batteries at the same time. When the engine is running leave the switch on all. Now when you stop and are using the boat to entertain or for leisure time switch the battery switch to number 2, now your boat is only using the house battery for all the 12volt power on board. You can continue in this position until you run out of power or are ready to go with the motor again. When you are ready to start the motor flip the switch back to number 1 position and start the motor and again set the switch to all and the engine will charge both batteries again. When you are finished boating and heading home turn the battery switch to the off position this will mean that only the bilge pump will be powered up. This is the safest way to leave your boat as the bilge pump needs to be able to get power for as long as possible, this is also good security as the boat will not start with the switch in the off position. If you do leave anything on by accident the battery switch will take care of that.

However there are exceptions to this rule and this is were most boaters get caught!!

The exception is if you have a 120/12 fridge, or other accessories have been added like amps and electronics. A lot of boaters or installers will wire direct to battery which can be a no, no! I have seen amps wired to the start battery. Nothing but the battery switch, trim pump and charger should be hooked to the start battery period. If you look at your start battery there should only be three red wires maximum and four black wires maximum. I will explain on a small runabout they can and do use the battery as a terminal block in other words they bring the boat trim pump, bilge pump, boat main, and the motor lead to the positive terminal. The motor trim pump and boat grounds to the negative terminal this is due to the lack of accessories that this type of boat has. If you start to load up your small boat with chargers and accessories you will have to install terminal blocks as you wont be able to get a nut on the posts any more. Never use the battery as a terminal block for a pile of wires, this is particularly true after you install a charger. your battery will not last long at all. On a small cruiser boat you should have three red wires to the positive terminal of the start battery , and they are charger wire, the wire to battery switch and the trim pump wire that's it no more. The negative terminal should have the charger wire, engine ground wire, trim pump ground and a jumper or bond wire to join all the negative battery terminals together. If your boat has any more wires than this on the start battery you will need to trace them and move them to another location to either pick up power or locate a ground. As boats get older and have been passed through many owners and technicians hands the batteries start to look like one of those plug adaptors at home with a dozen extension cords run to it, a wiring night mare which is a fire hazard. In many cases what happens is one or more of these wires have a draw on them. Which means that even if you turn off the battery switch there is a power drain on the battery, someone by passed the switch or terminal bar and ran a circuit directly to the battery. The worse culprit for this is a fridge, it will kill a battery in mere hours. So if you loose 120 volt power (shore power) to the boat the fridge automatically cycles over to 12 volt. If the fridge by passes the battery switch that you have turned off, the battery or batteries will only last a day or so and be stone dead. Now you have no bilge pumps or any protection on the boat.

The problem with this is once the batteries are stone dead the charger can be turned back on but it will not recognize that there is a battery to charge and the system stays dead. Most new chargers require a return of power from a battery to go ahead and charge. So a dead battery will not start to receive a charge at all. If a battery goes completely dead you will need to use another charger to start the recharge program on the battery and then reattach the battery to your on board charger.

TWIN MOTORS GENERATOR WITH FOUR BATTERIES

3- The third set up is the cruiser system set up , this is where the boat has a full 120 volt shore power system and multiple batteries with possible generator system. This battery set up can appear to be more complex and will usually have multiple battery switches and a minimum of three batteries and if rigged with generator four batteries. The reason for the multiple battery switches is to prevent the two alternators charging a single circuit. This set up is not really complex you just have to break it down into its components, to understand. The port motor side which usually has the house battery (s) attached to it, and the starboard motor side represented by a single battery start system. The generator is a simple single battery start system. In 99% of the cases these battery switches never get touched the boater relies on the charger to maintain the 12 volt systems and simply replaces batteries as they give up over the time of boat ownership.

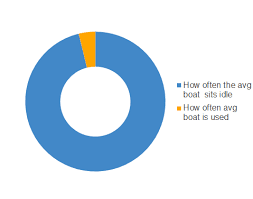

So why do batteries in my car last for years and in my boat I am replacing batteries every couple of years? Well there is a simple answer to this question when we leave our boats unattended with all the systems still running the batteries are taking a constant charge, when this happens the batteries never get a chance to cool down. What is happening?, the batteries are slowly being boiled dry. This is why technicians are checking the level in the maintainable batteries on your boat and having to add distilled water to them, once you start having to do this the batteries are already dieing a slow death. You can boil your batteries dry, the batteries will get so hot they will explode. If you board your boat and smell a sulphur smell immediately shut the charger down. Not only are the batteries affected by this constant charge problem, but over charged batteries will eat up battery chargers. Do you ever wonder why alternators and starters are a constantly being swapped out on boats. These part failures are quite often due to bad batteries. The effects of overcharging and bad batteries are felt all over the boat. If boat owners would shut the chargers down once in a while and give the system a break instead of leaving on the charger until they start the motor thus immediately the alternator begins to charge, providing no charging break for the batteries. If the batteries were given a charging break they would have a longer life. A lot of the time the charger is on, it is not charging the batteries. The batteries are probably fully charged, but instead the charger is trying to maitain a load. (something is on drawing a small amount of power from the battery).

All the same rules that we have previously discussed apply to a multiple battery system. Problems associated with battery life include, jumping accessories directly to the batteries, bad terminal connection and not using the switches to shut the boat down when you are gone for days at a time. On a multiple motor multiple battery system you have shore power to keep the necessities running you don't need to leave the 12 volt system on all the time. If you use the 12 volt systems in the correct way you can extend battery life and have a safer boat.

Most boaters don't understand or know the correct way to use the battery switches in the boat to maintain and extend the life of thier batteries.

4- Chargers and Batteries. I cannot stress enough the importance of having the correct batteries in the right places. Start batteries in the start location, deep cycle batteries in the house location and clean correct terminal attachments. Do not have a pile of cables on your batteries. When it comes to the order with which the wires go on the batteries, there is a rule here to do not just put them on in any order. The first wire on the terminal is always the charger wire. The reason for this is many chargers have a heat sensor function that shuts the charger down in the case of a hot battery. This function only works if the battery charger wire is the first wire on the battery. If the charger wire is second or third the heat will travel up the other wires first (use the larger wires as a heat sink) and the battery will burn up before the charger can recognize a problem. I am sure if you have owned boats for long, you have seen burnt cable ends or damaged terminals on batteries, this is why.(incorrect order of wires on the battery post)

SOME TIPS

1-If you are going to swap the batteries to gel cell batteries you must be sure the charger is compatible

2-Run the charger wires directly to the battery not to the battery switch.

3-Be sure all the negative terminals on all batteries are tied together.

4-Do not use cheap automotive battery cables, they will rust away every time.

5-It is necessary to use actual stainless steel nuts and not wing nuts to attach cables to the batteries

6-Be sure each positive charger wire has s fuse in line

7-Always use correct size wires at the battery

8-Batteries will freeze if not at a full charge

9-Battery boxes will collect water make sure that they are dry and clean

10-Be sure your batteries are all tied down with battery tie downs

11-Inspect your batteries regularly (once a month) don't just look, check the terminals. Loose terminals will melt away under load.

12-Keep a container of distilled water on board if you have serviceable batteries and check the levels every month or so.

13-Do not always believe a battery load tester if you think the battery is a problem change it, it is always a good idea to keep a spare fully charged battery on board if you have the room to do so.

14-If you have a generator on board and the batteries go down remember the generator battery is isolated from the rest of the boat you can start the generator and switch the battery charger on and after twenty minutes the engines will start

15-Keep all battery wires the correct length and do not run them close to heat sources

16-Clean terminal connections remove any corrosion from wire ends and terminals

If you have a fishing boat or a boat were there is a bow thruster trolling motor or loads of electronics and there are extra batteries installed, have a technician or some one other than your resident boater expert explain how these batteries are wired were they get a charge and how the system works. This is true in the case of an emergency were you need to disable a system due to heat or fire. Be informed and you will have a safer boating experience.

To guarantee access to all of Boat Nut Magazine articles, pictures and featured services visit the official Boat Nut Magazine ©™ website. Be sure to reply to the Boat Nut Association registration on our site for the latest Boat Nut weekly and monthly news letters and opportunities.

Copyright 2015 © Boat Nut Media, Toronto, Ontario. All rights reserved. No part of this information/publications may be stored in a retrieval system, transmitted, or reproduced in any way, including but not limited to photocopy, magnetic, or other record, without prior agreement and written permission of the publisher, Boat Nuts Media ©™ No liability is assumed with respect to the information provided.